How can healthcare benefit from better logistics planning?

In the world of logistics, lack of visibility creates uncertainty, costs money, and creates unhappy customers. We have solutions that solve all three.

For many industries, creating efficient logistics plans extends well beyond managing the transit of things from one place to another. It's an oversimplification to reduce the job of a logistics manager to get things to their final destinations as quickly as possible.

Creating cost-effective plans does not always require speed. In fact, for most supply chain managers, visibility and precision are far greater allies.

Being able to understand precisely when things will arrive, where they are when they arrive, and how that timing lines up with other moving parts is the key to creating cost-savings in logistics planning - and this is valid for all outdoor, indoor and condition tracking, ideally in combination. Doing it right results not only in more efficient operations, but it makes for happier customers.

To gain a better grasp of the daily challenges that logistic planners face, let's look at the example of maintaining equipment in healthcare.

Visibility through the scope of healthcare

Hospitals and healthcare facilities are like mini cities, with some employing as many as 20,000 people. They're also host to millions of dollars of medical devices and machines that require delivery and upkeep, creating a significant market for logistics in healthcare alone. In fact, according to a recent report, the global healthcare asset management market is expected to reach US$29.6 million by 2020.

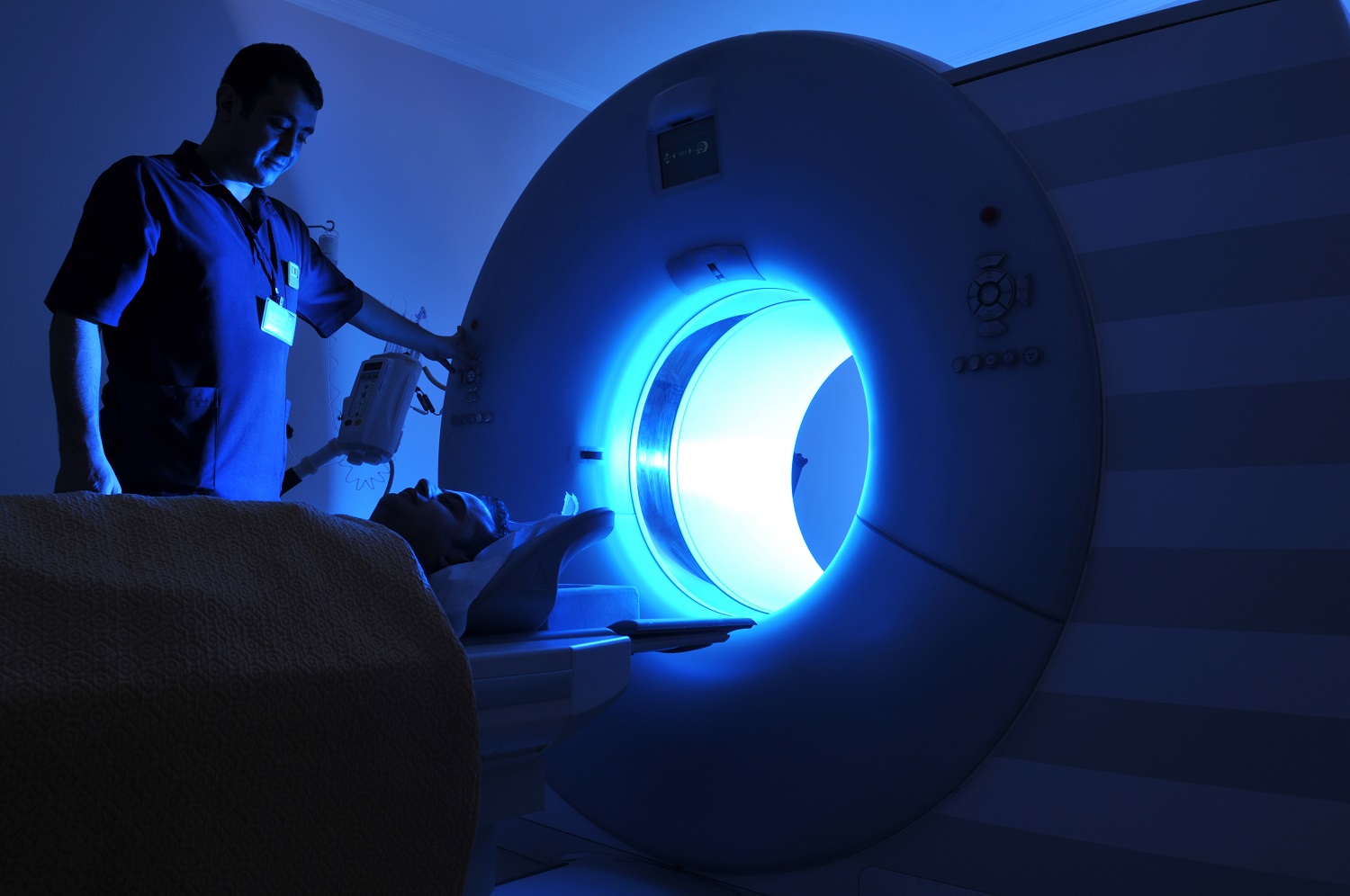

An MRI machine can leave hospitals with a hefty price tag of around US$500,000.

Consider the financial impact of operating an MRI machine - aside from the cost, they often require specialized rooms to operate in, doubling the cost of installation. MRI machines must be updated and maintained by the manufacturer, normally performed by a specialized engineer with a very expensive hourly rate.

Now add a doctor, technician, and radiologist who all have to be present and paid for during normal operations. All that accounts for the $2,000-$2,600 a one-hour MRI scan usually costs. Doing the math, during the 30-60 hours a MRI machine is down for maintenance on average per year – in addition to the costs of repair – the hospital is spending money on idle staff, and losing between $30,000 and $156,000!

Suppose you're the logistics planner for a company that provides these machines. You've sent a shipment of parts needed for a repair to a hospital campus. In traditional practice, you add a safety buffer between the time the parts will be delivered, and the time the technician will arrive.

The parts are most likely to arrive Tuesday morning, but they could be as late as Wednesday. Thus, you schedule the technician that needs the parts to arrive on Wednesday afternoon.

Without visibility, the manager only knows that the parts arrived at the receiving station. They could have been moved to a storage facility, or to the building where the work will take place somewhere between the basement and 22nd floor, or even placed on a hand truck and forgotten about.

When the engineer arrives, they are then forced to spend hours simply locating the parts needed for maintenance.

That delay has a domino effect. The engineer must then charge additional time as they wait for parts to be found. The scheduled completion time for the maintenance is then pushed back, which in turn causes cancellations for the doctors, technicians, and patients who were scheduled to use the equipment.

Logistics managers struggle with these same costly scenarios across multiple industries; manufacturing, automotive, healthcare, and retail all see loss due to a lack of visibility.

The solution to the visibility challenge

By working directly with industry professionals to identify how these problems arise, we've built solutions to solve the lack of visibility through every stage of planning and delivery, and it works for every industry.

First, using HERE tools, logistics planners can provide a far more precise time of arrival because we have the location data required to accurately plan a journey across multimodal transportation.

Our solutions can project how long it will take an item to move from boat, to train, to truck, as well as calculating the waiting time at customs and waypoints at each. Once shipments enter their last mile, we can account for traffic and weather issues, and our systems can help re-route to avoid those problems.

When an item arrives at its final stop, indoor tracking takes up the job of giving logistics managers a perfect understanding of precisely where parts and supplies are located. Our tools enable planners to understand where things are at that precise moment, rather than where they were when they were last checked in.

Our available technology extends even into visibility of the condition of shipments. As an example, we can take in information provided by gyroscopes and temperature sensors. With that data, we can raise or lower our confidence about the condition of a part if it's been exposed to severe temperatures, or if it suffered a hard fall in transit.

With this extensive information, planners no longer need to buffer their delivery times. They can more effectively send people exactly where they're needed, exactly when they're needed.

And, if a dead on arrival (DOA) event takes place en route to the hospital, the back office can immediately react by re-ordering an identical part. The logistics planner is able to respond so quickly that the customer may not even notice the DOA of the initial shipment.

Sign up for our newsletter

Why sign up:

- Latest offers and discounts

- Tailored content delivered weekly

- Exclusive events

- One click to unsubscribe