The Dock Schedule Optimizer helps cut the traffic in your supply chain

In logistics management, profit and loss are distilled to time moving and time standing still. Keeping things moving efficiently through the choke points of the supply chain is a challenge – met by Camelot’s Dock Schedule Optimizer.

If you’re in supply chain, you may imagine delivery vehicles filled with goods, each floating along beautiful, picturesque highways. They might even cruise through traffic-free roads, nestled between green fields under a canopy of deep blue sky.

Then, seven trucks arrive at a facility with three docks – and grey clouds roll in to dampen our vision of seamless, efficient fulfilment.

This is all too common, and it’s not an easy problem to solve, primarily due to the number of players involved. A shipper may be contracting a third-party logistics provider, who in turn retains a freight carrier who uses a sub-contractor who employs a driver, all of whom are completely disconnected from the dock manager.

Delays happen. A truck may be late departing from its previous waypoint, or a driver may be nearing a mandatory break, or weather has caused traffic. That information isn’t proactively provided to the dock manager, who is usually doing a heroic job of directing trucks in and out of the facility, while directing workers to prepare to load and unload goods.

In that situation, loss is created when trucks have to wait long periods of time to be serviced. Each is burning fuel, and more importantly, each one is standing still. This not only reduces efficiency, it causes traffic both inside the facility, and on the roads around the facility, resulting in significant demurrage costs.

Dock Schedule Optimizer solves this. A motivation for incorporating time slot management systems is, in addition to the better use of charging capacity, the avoidance of demurrage. As a powerful, connected solution, the app collects real-time data from all the key players, combines that data into a simple, intelligent interface, and automatically feeds critical information back to each of the point in the supply chain.

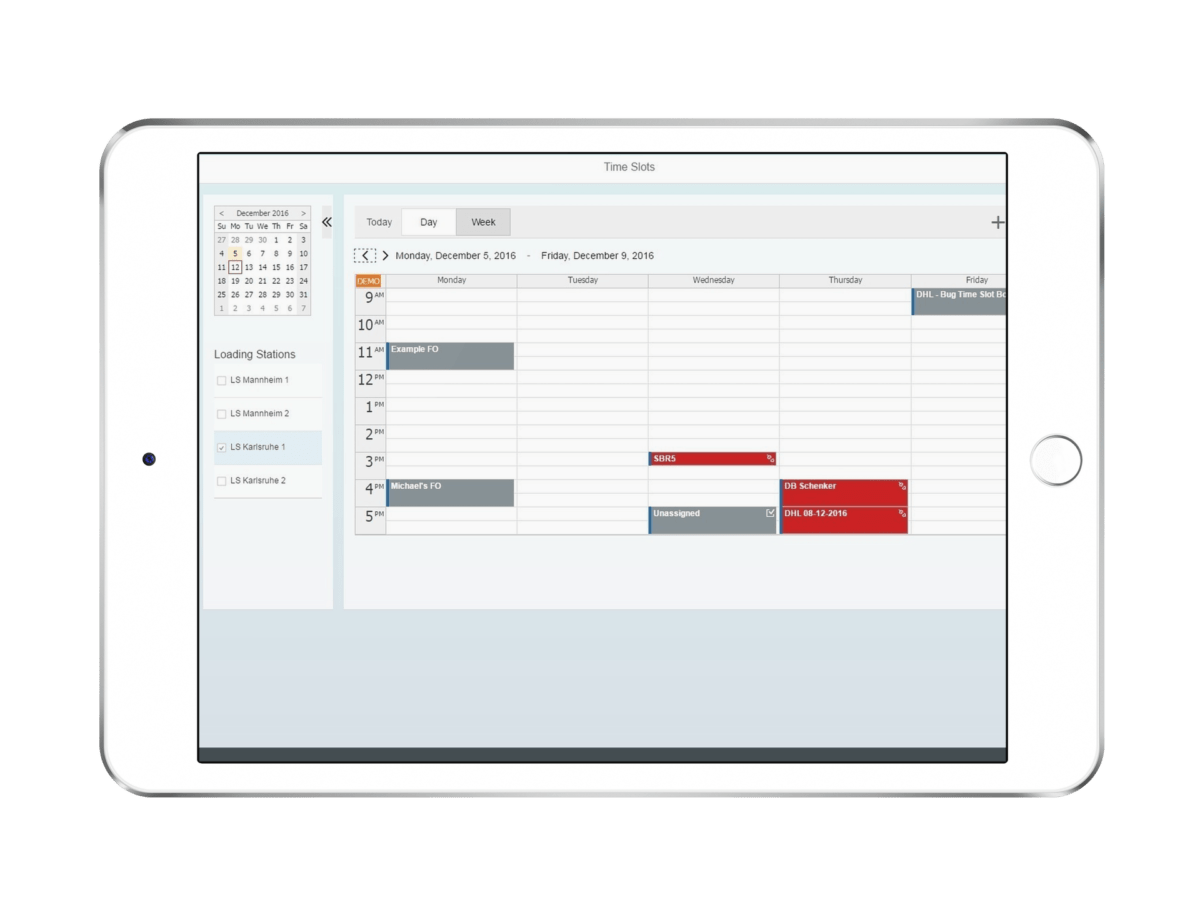

With a simple interface, a dock manager can schedule each of their bays for a full day’s work, accommodating differing in and out times per truck and per shipment. That schedule is then shared across to all workers, carriers and drivers that will be managing the movement of goods in the facility that day.

Because all parties are connected through the same application, the need for multiple modes of communication is reduced. As soon as the scheduler plans a timeslot, the driver’s app alerts them when to arrive, the shipper can provide visibility to their clients, and facility workers know which goods to queue up.

But into every shipment, a little rain must fall – or a little traffic must jam.

When delays occur, Dock Schedule Optimizer is intelligent enough to automatically alert the facility manager before the truck is late. The manager can then move the schedule to fill the blank, and update trucks that are ready to be loaded and unloaded. Because it all happens seamlessly across a single app drivers and shippers are all informed without the need for a load of phone calls, radio calls and emails.

In practice, the app has reduced waiting time by 20-30%, as well as dramatically reducing the amount of truck parking needed on factory premises. Facilities were able to process 10-20% more freight orders per time unit, and new business partners have been integrated at lightning speed.

Made by Camelot ITLab, the app leverages powerful solutions like the SAP Transportation Management backbone, along with HERE Routing, Truck and Historical Traffic APIs. The app is already available from the SAP App Store.

Have your say

Sign up for our newsletter

Why sign up:

- Latest offers and discounts

- Tailored content delivered weekly

- Exclusive events

- One click to unsubscribe